Maintenance of Injector and Injector vacuum

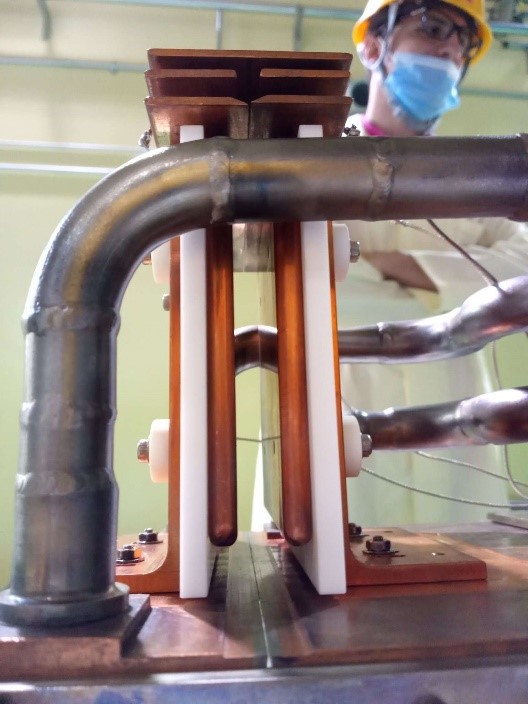

The maintenance of the injector and its annexed LEBT (Low Energy Beam transport) was completed with the maintenance of the EMU (Emittance Meter Unit): visual inspection of tungsten tiles, insulation check among electrodes and ground, check of slit integrity and slit thickness were performed. The slit thickness (0,1mm) was found to be aligned with the values measured last year and judged satisfactory to operate in Phase B+.

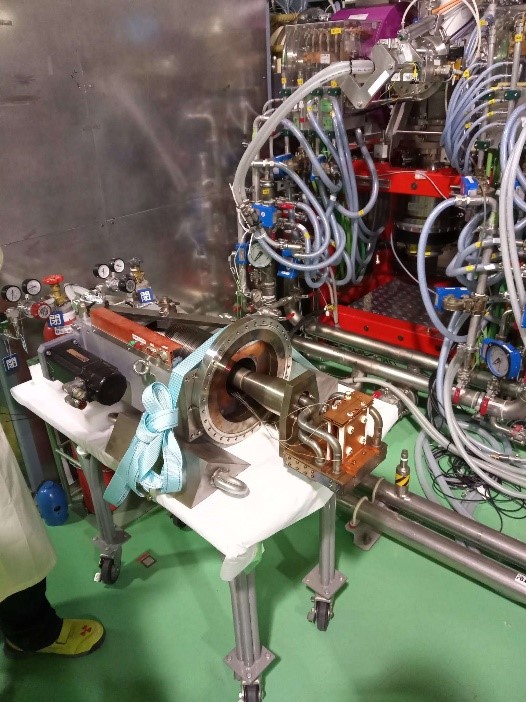

EMU extracted from the LEBT (left) and close-up on the EMU slits (right). The EMU aims to measure the emittance profile of the beam.

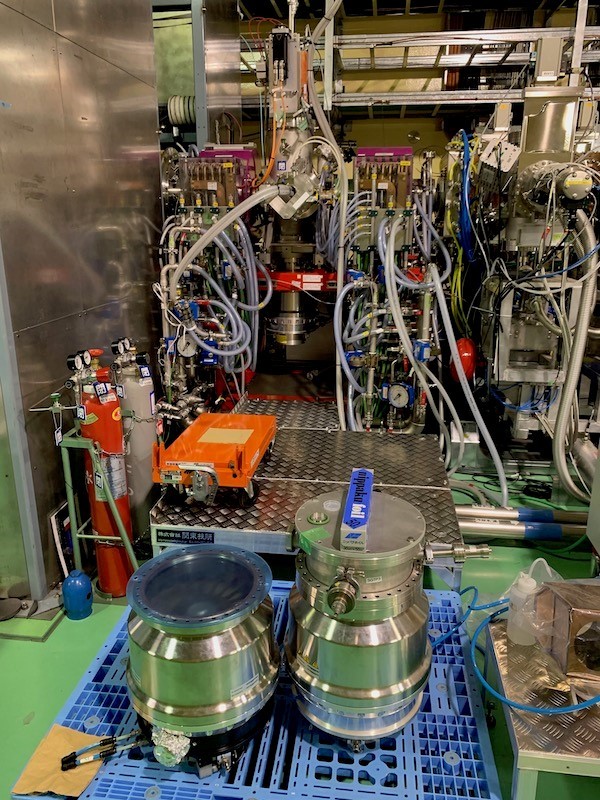

Before resuming injector operation in November, the maintenance of the injector vacuum chamber has to be completed. This week the former turbomolecular pump was replaced by an identical one.

Replacement of the Injector vacuum chamber turbomolecular pump: the position, size and weight of the pump make this operation challenging. This time the flat bench was newly installed for easy access.

HEBT (High Energy Beam transport) commissioning

The HEBT (High Energy Beam Transport) and the Beam Dump are the last parts of the LIPAc currently in commissioning phase. After few issues on the HEBT cooling skid and one of its vacuum chambers (HEBT sector IV), this week the skid operation was successfully resumed and the vacuum in sector IV recovered after fixing the leak at the viewport flange. From next week the checks and fine tuning of the HEBT magnets can restart with CIEMAT remote support.

Disclaimer: the information reported is not meant to be technically complete and doesn’t cover all the activities currently carried out on LIPAc.