Injector

Plasma conditioning with H2 gas is regularly on-going while the vault is closed, with no issues.

The cooling panels of the LET3 and LET4 cubicles were delivered on June 28. The intervention to replace them was completed on July 01 resuming the skid operation and confirming that the solenoid PS can be turned on.

PPS (Personal Protection System) test for Injector was performed on July 02 and Injector conditioning with proton beam extraction resumed smoothly afterwards.

Radio Frequency (RF) System and RFQ cavity

After completing the cleaning and the reassembly of the flow regulators on the manifolds of the HVPS (High Voltage Power Supplies) the RF injection with RFQ condition was resumed.

RF system shows a stable behaviour and conditioning could be resumed from 5%DC and quickly ramped up to 6,7%DC (1ms pulse for 15ms period). We experienced interruptions due again to low flow rate in HVPS: when inspected the flow regulators are found to be clean, but the intervention might have jeopardized their functionality: a solution was found to modify the flow regulators and set the flow rate to higher values. The solution was successfully applied to several HVPS and will be extended to other modules whenever RF injection is interrupted by interlocks due to low mass flow.

In preparation of the beam operation validation of the upgrade of the timing system and validation of new software for the circulators are also being finalized.

Medium Energy Beam Transport (MEBT)

The conditioning of the bunchers resumed compatibly with the concurrent intervention on the RF water cooling lines: the conditioning of both bunchers was completed up to nominal voltage of 350kV. High voltage instabilities in the buncher#2 are being investigated.

High Energy Beam Transport (HEBT)

The final debugging of the HEBT/BD LCS (Local Control system) and the MPS (Machine Protection System) checks were performed with constant support by remote sessions of CIEMAT colleagues. The connection of the HEBT/BD LCS to the LIPAc-net is planned early next week and remote sessions with CIEMAT will be put on-hold until the summer maintenance period. The finalization of the HEBT vacuum machine state (not mandatory for beam operation) will be completed in September.

Beam Dump

The water circulation including the Beam Dump cartridge in its main operational mode – during beam operation – is stable. A new cooling chiller for BD skid oxygen control line has been installed and its powering was completed on July 01.

Some final adjustement on the fixing screws of the BD shield were carried out in the vault and now the installation is definitely completed.

Beam Instrumentation

The conditioning of RGBLM (Residual Gas Bunch Length Monitor) for achieving the maximum high voltage at bottom plate electrode is completed.

Control System

MPS pre-check for the beam operation were conducted on 28 June. Only few points were found to be monitored to confirm their functionality but they are not critical for starting the initial beam operation.

The CCR OPI improvement is mostly completed and acceptance check is planned after HEBT LCS is integrated (by connecting it to the LIPAc-net).

Ancillaries

Ion exchange resins in RFQ skid water treatment line have been replaced on July 01.

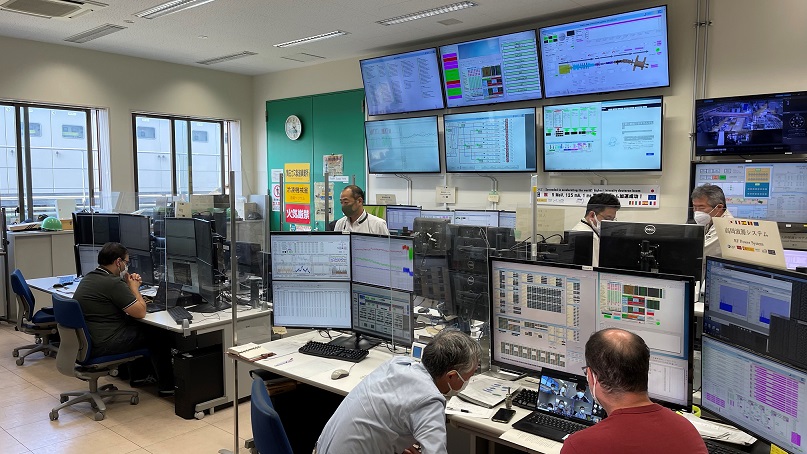

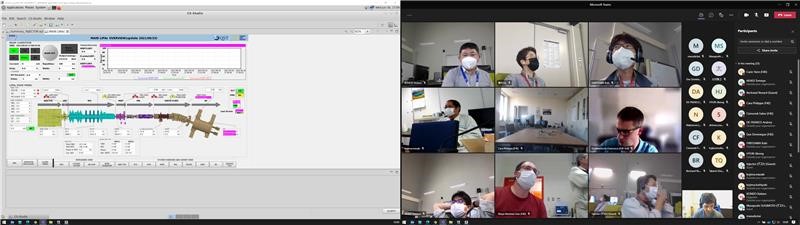

MSteams operation rehearsal from CCR (Central Control Room), LCR (Local Control Room) and remote connection from Garching

A beam operation rehearsal with MS Teams was carried out on 30 June: the aim was to check the arrangement of the different operators in CCR and LCR, and perform a test of communication with Teams. All the communication was strictly conducted through Teams and direct verbal communication was avoided.

During the rehearsal the vault was closed and the RFQ conditioning started with RF injection in the cavity. F4E colleagues from Garching were also actively involved.

Steady progress towards the beam operation!

Disclaimer: the information reported is not meant to be technically complete and doesn’t cover all the activities currently carried out on LIPAc.