One of the challenges of the fusion machines … [read more]

Author: Philippe Cara

IFMIF/EVEDA – Engineering and validation of equipment in progress

Follow the link to access the newsline in F4E website

LIPAc operation broadcast LIVE online

On 27 July 2018, from 4pm JST (9am CEST) a special broadcasting took place from LIPAc’s control room, with explanations, interviews to the LIPAc Operation Team staff about the different subsystems and the operational aspects. The engineers from Europe were also interviewed and presented their own institutes and expectations for the future.

http://live.nicovideo.jp/gate/lv314610330

10th LIPAc Technical Meeting (LTM10)

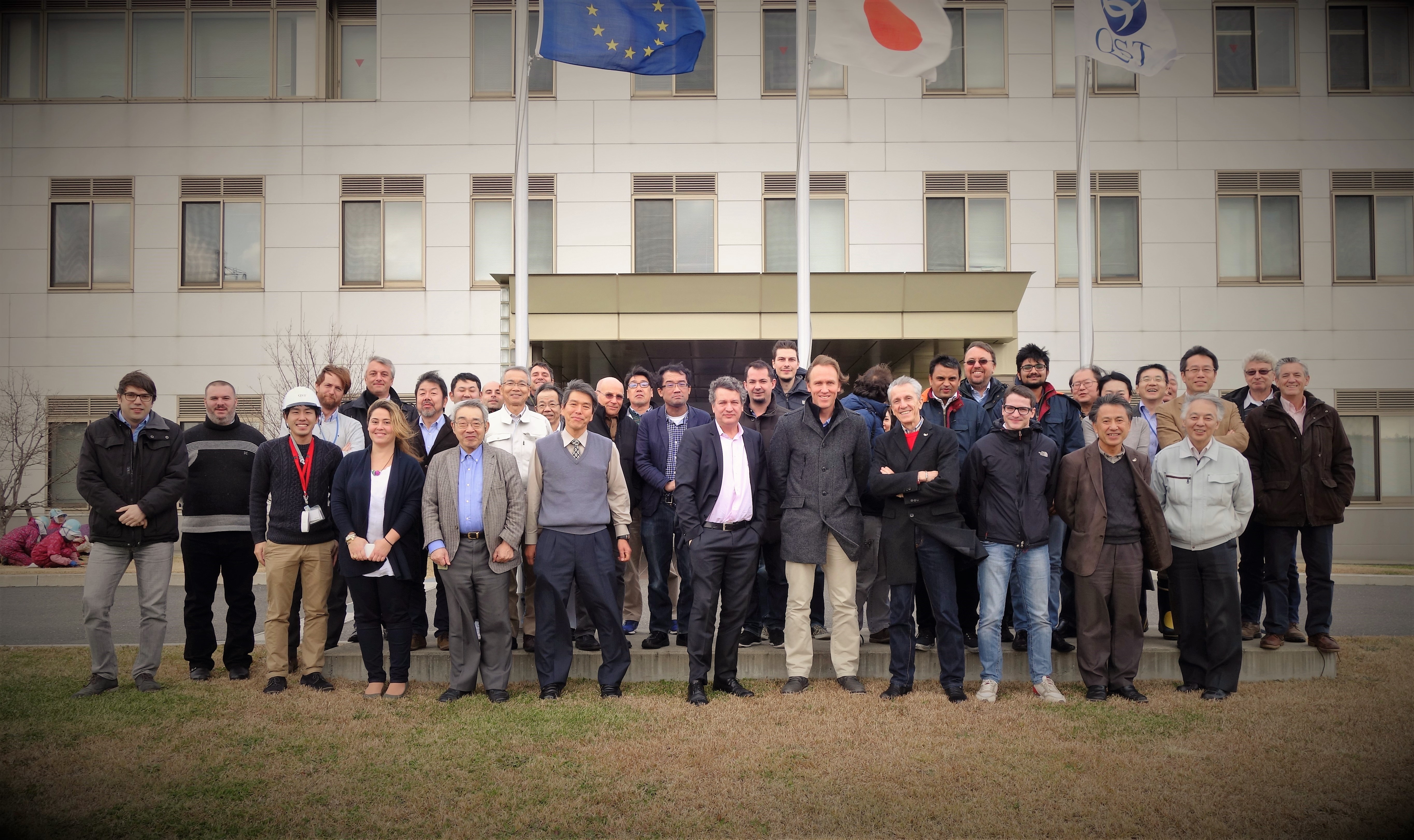

The tenth LIPAc Technical Meeting 10 (LTM10) was held in Rokkasho (Japan) from November 14th until 17th, where the current status of the design, manufacturing, installation and commissioning of the LIPAc accelerator’s components were discussed. More than 30 experts from laboratories in Europe, including CIEMAT (Madrid, Spain), CEA (Saclay, France) INFN (Legnaro, Italy); and Japan, including QST (Rokkasho, Japan) and KEK (on behalf of QST) attended the meeting, which was coordinated by the LIPAc Project Team and QST. In addition, videoconferencing was available to allow remote participation of EU colleagues who could not attend in person.

Detailed discussions were held to reach common agreement on the key technical issues that have arisen, and progress was reported on many aspects of the project. The following gives an overview of the progress made in key areas:

Injector:

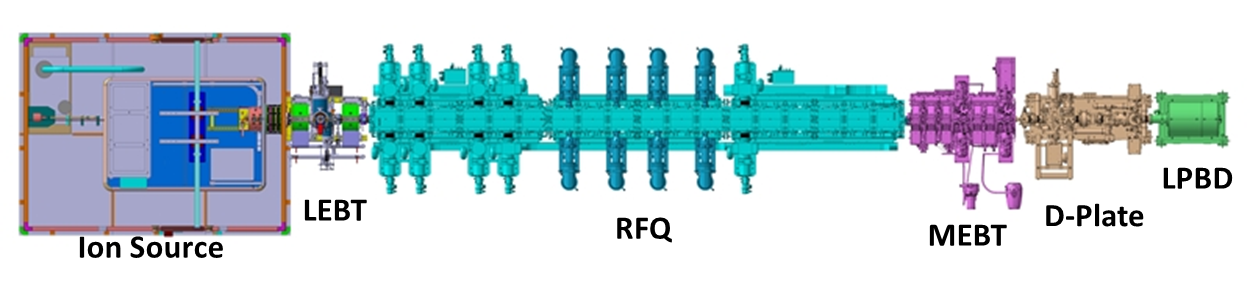

Full commencement of phase “B” commissioning was announced, and the LEBT (Low Energy Beam Transport) was removed to allow final positioning of the RFQ. During the last campaign of Injector commissioning, a current of 112 mA with acceptable emittance in CW operation was achieved. While this falls short of the goal, this represents an excellent improvement. Further adjustments must be made to the accelerator column, followed by 24/7 beam extraction, to achieve the target parameters.

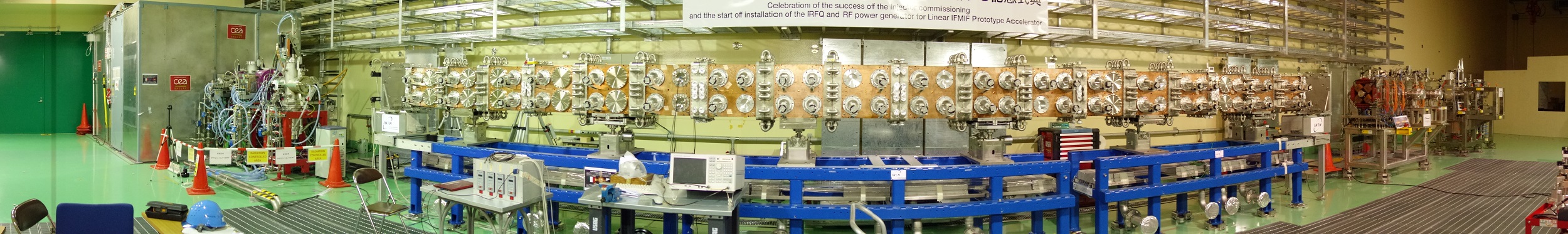

RFQ:

The bead pull measurements were successfully completed, and the final measured frequency was equal to 174.089 MHz. When scaled to the normal operating temperature of 20 °C and considering the effects of vacuum and beam loading, this is equivalent to 175.014 MHz. Following LEBT removal, the RFQ super modules were placed in their final position, and aligned within a tolerance of 50 µm. The RFQ was pumped down and the correct vacuum conditions for the three super-modules were achieved. The RFQ can now be baked-out before final assembly can proceed. Control cubicles and junction boxes were installed and are now being configured.

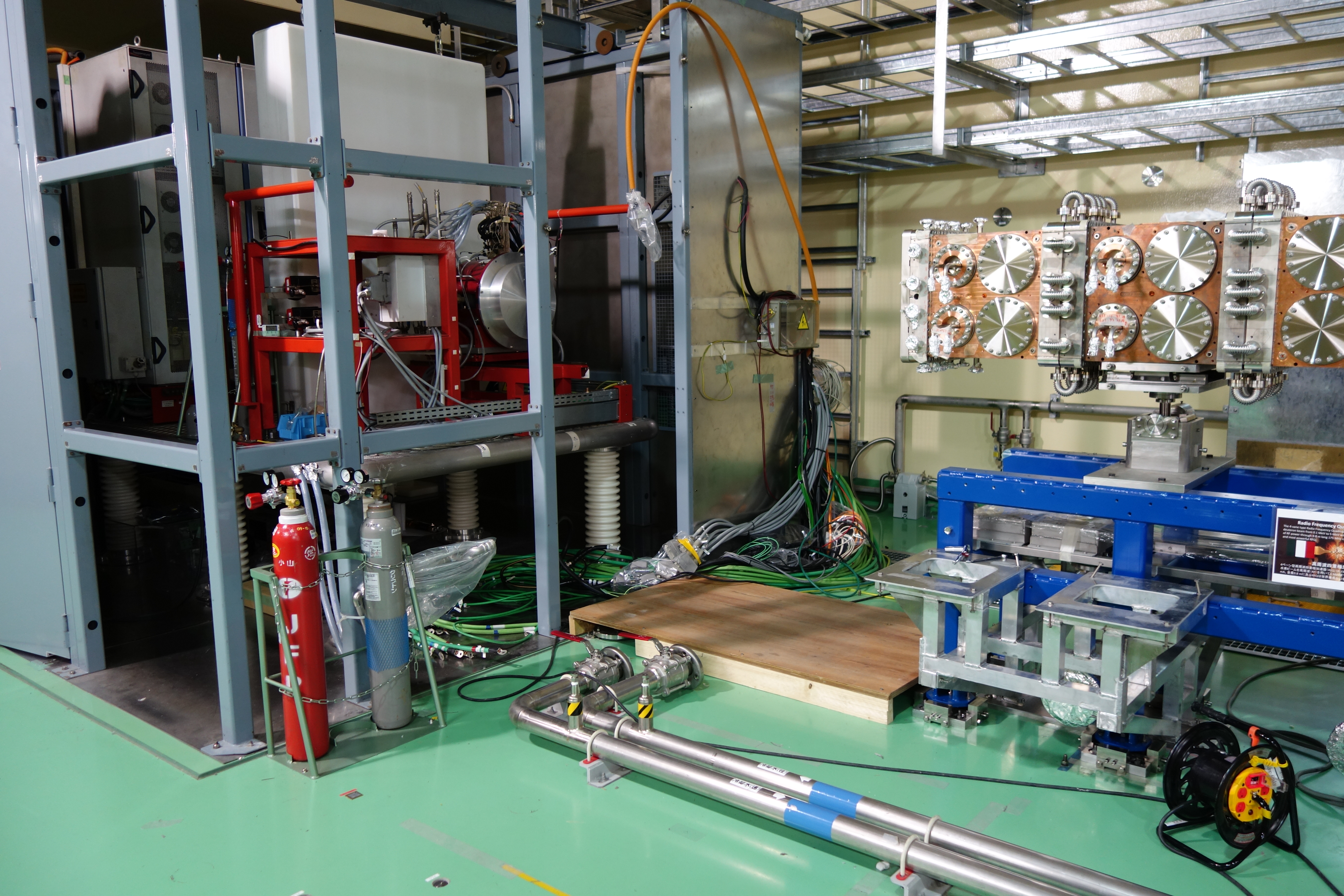

RF System and Coaxial lines:

Tangible progress was made since LTM09, which was held in April 2016. RF module 02 for the SRF LINAc was tested and sent to Saclay for Sathori test stand. After use in Saclay, it will be sent to Rokkasho for installation in Rokkasho. RF module 03 will be sent to Rokkasho on 30th of November 2016, together with the SRF LINAc coaxial lines, while RF module 04 is now in the final stages of preparation at Indra’s facilities, and is expected to be ready for shipment to Rokkasho in January 2017. The installation of the RF cooling system onsite is almost complete. The RFQ coaxial lines have been installed in preliminary position. Final positioning will be made after the connection is made to the RFQ.

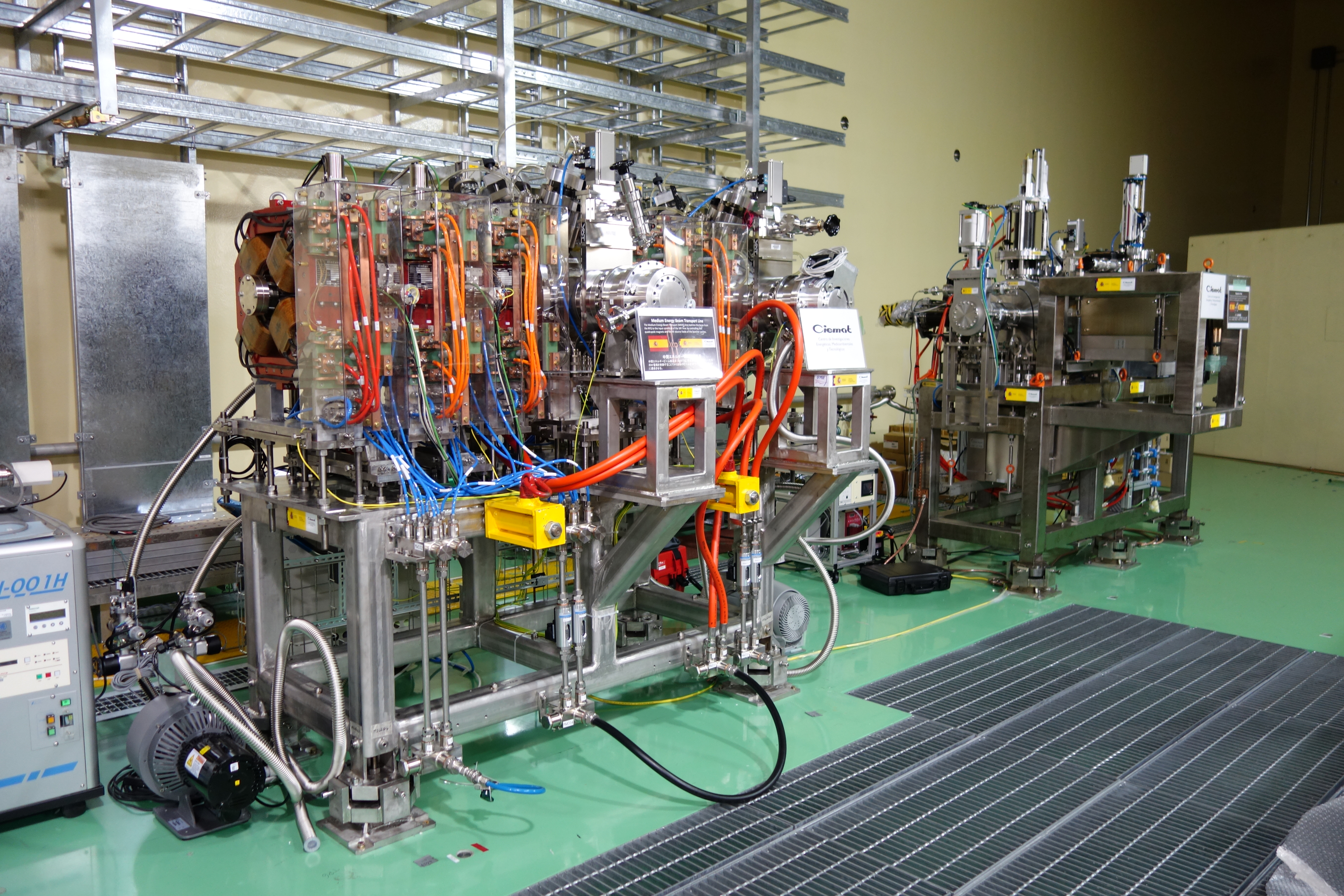

MEBT and D-Plate:

Most of the installation and commissioning activities of the MEBT and D-plate were performed in parallel during pre-commissioning last summer 2016. Preparation for the next installation campaign already started with the objective to reach the LIPAc phase B configuration (Injector-RFQ-MEBT-Dplate and LPBD) next year. The displacement of the MEBT to its final position is planned beginning of 2017. Once it is validated by an alignment survey, it will be followed by displacement and alignment of the Dplate. Then the ancillaries (cabling, piping, compressed air and vacuum) will be installed on both equipment and tested. The integration of LCD into CCS will conclude this campaign; at least for these two accelerator components, driving to their check out and commissioning.

SRF Linac and Cleanroom:

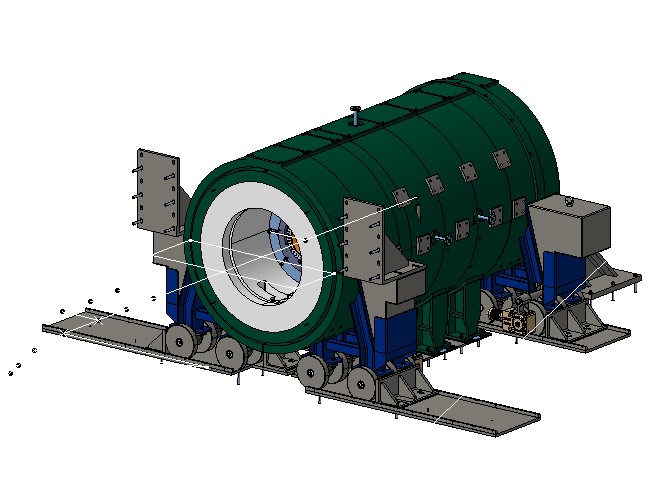

All the main components of the cryomodule are expected at CEA (Saclay, France) by the end of March 2017 and ready for shipment to Rokkasho by the end of April 2016. It was agreed that the assembly of the cryomodule will be performed at Rokkasho in dedicated clean room which will be available in Rokkasho by the end October 2017.

The Sathori test stand is prepared and awaiting commissioning of the power supplies and RF modules. CEA expect to start testing the cavities at the beginning of 2017

Cryoplant:

Most of the components for the cryoplant have been delivered to Rokkasho. The final components, including the helium buffer tank and the control cubicles, will be delivered during December 2016. The installation activities started during November, with the first major components being installed in their final locations and the commencement of piping works. Civil work associated with the cryoplant is also progressing with the construction of the foundations for the Nitrogen and Helium storage tanks.

HEBT/BD:

The HEBT manufacturing drawings have been completed and many components, such as the water cooling system, and associated pipe, fittings and valves; have been manufactured or procured and delivered to Rokkasho. 4 out of 5 HEBT support frames have been manufactured at CIEMAT, and manufacturing of the first quadrupole is complete. For the beam dump, the inner cone of the first prototype has been manufactured, and a second prototype is being manufactured. The acceptance tests for the beam dump shield are expected to proceed at CIEMAT in December 2016. The main steel shielding and mobile shielding manufacture is now in an advanced state, and final acceptance tests are expected in February 2017. The cooling system design continues, but manufacture will need to be accelerated to match with the current schedule.

Control system:

Phase B commissioning is approaching, and as such, the dedicated control configuration is required for the control system. An additional 42 signals are required, a test bench for the timing system has been prepared, and the program for data creation is being prepared. Local control system integration for phase B will include the RFQ, RF/LLRF, MEBT and D-plate. The Central Control System upgrade contract is expected to start in January 2017. Moreover the need for a beam simulation study to optimize the configuration of beam was recognized as being urgent. Data event recording tool must be implemented, and the operational screens in the control room are being prepared according to the needs of the different subsystems.

The next meeting LTM11 will be held between April and May 2017, with the location yet to be decided.

9th LIPAc Technical Meeting

The 9th LIPAc Technical Meeting (LTM09) was held at the IFERC Site in Rokkasho, Japan, from 19th to 22nd April 2016. More than 40 experts from different involved institutes, including CEA (Saclay, France), INFN (Legnaro, Italy), QST (Rokkasho, Japan), CIEMAT (Madrid, Spain), F4E (Garching, Germany) and the IFMIF/EVEDA Project Team; attended the meeting. In addition, Japanese experts from KEK and J-PARC attended on behalf of QST.

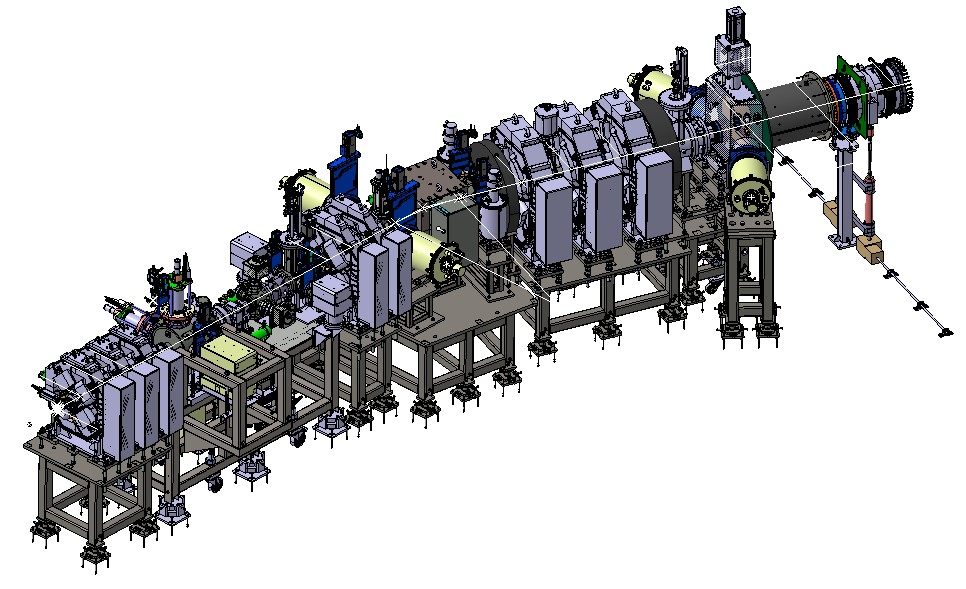

Many satellite meetings were held, with devoted discussions on most of the accelerator systems, including the MEBT (Medium Energy Beam Transport), HEBT (High Energy Beam Transport) and the Beam Dump; the control systems, including vacuum system integration and its overall process management, the control room configuration; the different phases of LIPAc commissioning, including integrated operation scenarios and beam dynamics issues; and the cryomodule assembly.

During the LTM, much detailed technical information was presented, highlighting the significant progress that has been made for the manufacture and installation of various components since the previous LTM08 held in Garching (Germany) on 24-26 November 2015.

The main outcomes presented during the meeting are listed below:

• Injector

Over the last 6 months injector operations have been very intense: 3 measurements campaigns were carried out as well as curative and major preventive maintenance. The deuteron beam commissioning performed in December 2015 gave promising results, the emittance met specifications at 20 % and 50 % duty cycle for currents of 110 mA at the level of the beam stop. In March 2016, the measurement campaign with a proton beam, which is a scaled version by a factor of 0.5 in intensity and energy, but with the same perveance as a deuteron beam, enabled to find a good working point at 10 % duty cycle. The last measurement campaign was very effective thanks to the careful maintenance performed and to Tracewin simulations which made it possible to determine the most interesting sets of machine parameters giving the best beam characteristic

- RF power systems

Remarkable progress was made for the RF system, with the delivery and installation inside RF power supply area of the Accelerator Building of all of the HVPSs and the first three RF Modules for the RFQ. The main cable trays, panel boards and grounding systems have also been installed, and the transformers and the HV breakers on the electrical platform are complete.

The four RF modules for the SRF LINAc have been manufactured, and the first unit has been partially tested and will soon be ready for shipment. It will be shipped to CEA Saclay for integration on the Sathori Test Stand.

- RFQ

The RFQ super module installation was successfully completed according to the schedule presented at LTM08 (Garching, Germany). The bead pull measurements will commence on 25/04/16 and will be completed by the end of July after 3 campaigns of measurement. The RFQ will then be relocated to its final position immediately afterwards.

The RFQ cooling skid and accessories are at Rokkasho and the water cooling skid requires some adjustment before its final installation/site commissioning.

- MEBT

The MEBT arrived in Rokkasho in March 2016, and was temporarily positioned inside the Accelerator Vault by the end of March. The electrical cubicles and other electrical equipment are expected to arrive in the middle of July, while the cooling skid, piping and associated accessories are currently being manufactured

- D-Plate

The D-plate was installed inside the Accelerator Vault in a temporary position, in April 2016.

- SRF Linac

While licensing activities for the complete cryomodule continue, the formal approval of the cavity design by KHK was obtained representing a great success for those involved.

Manufacturing contracts for all critical components have now been placed, and the tender process for a number of non-critical-path items has also been launched. Agreement has nearly been reached on the definition of the requirements for the clean room to be constructed at Rokkasho, and the tendering process for the clean room’s construction is expected to start by June.

- Cryoplant

The main cryogenic system components, including He compressors, oil removal system and cold box, have been manufactured and delivered to Rokkasho.

The requirements for the licensing of the cryoplant have been clarified. The cryoplant distribution piping and equipment are currently being designed.

- HEBT/Beam Dump

The HEBT water cooling skid, which will cool the magnet of the MEBT and HEBT, arrived in Rokkasho in January 2016. It was positioned inside the Accelerator HEX room and the piping is expected to start after the final positioning of the MEBT, which will intervene after the final positioning and back out of the RFQ.

A number of manufacturing contracts for the HEBT are ongoing, including the construction of the quadrupole and dipole. The design of the beam chambers is complete and the technical specifications have been prepared. The remaining components, i.e., power supply, supports, magnets coil system, vacuum pumps and associated equipment; have also been designed and are being procured.

Design for manufacture continues for both the Beam Dump low alloy steel shielding and mobile shielding, with manufacturing expected to start for both at the end of May 2016. Final assembly and acceptance tests are expected to commence in September. Manufacturing is progressing well for the Beam Dump cartridge.

- Control system

The dedicated Control Systems and LIPAc Operation satellite meeting was fruitful. It was identified that the integration of the different LCS into the CCS is on the critical path and mitigation actions should be considered. It was agreed also the need to tackle the various operational issues e.g. setup of the vacuum systems, identifying the thresholds for the MPS and setup of common operating procedures. An operating procedure for phase B, including a start-up procedure needs to be prepared urgently and missing operations with possible proposed configurations must be identified.

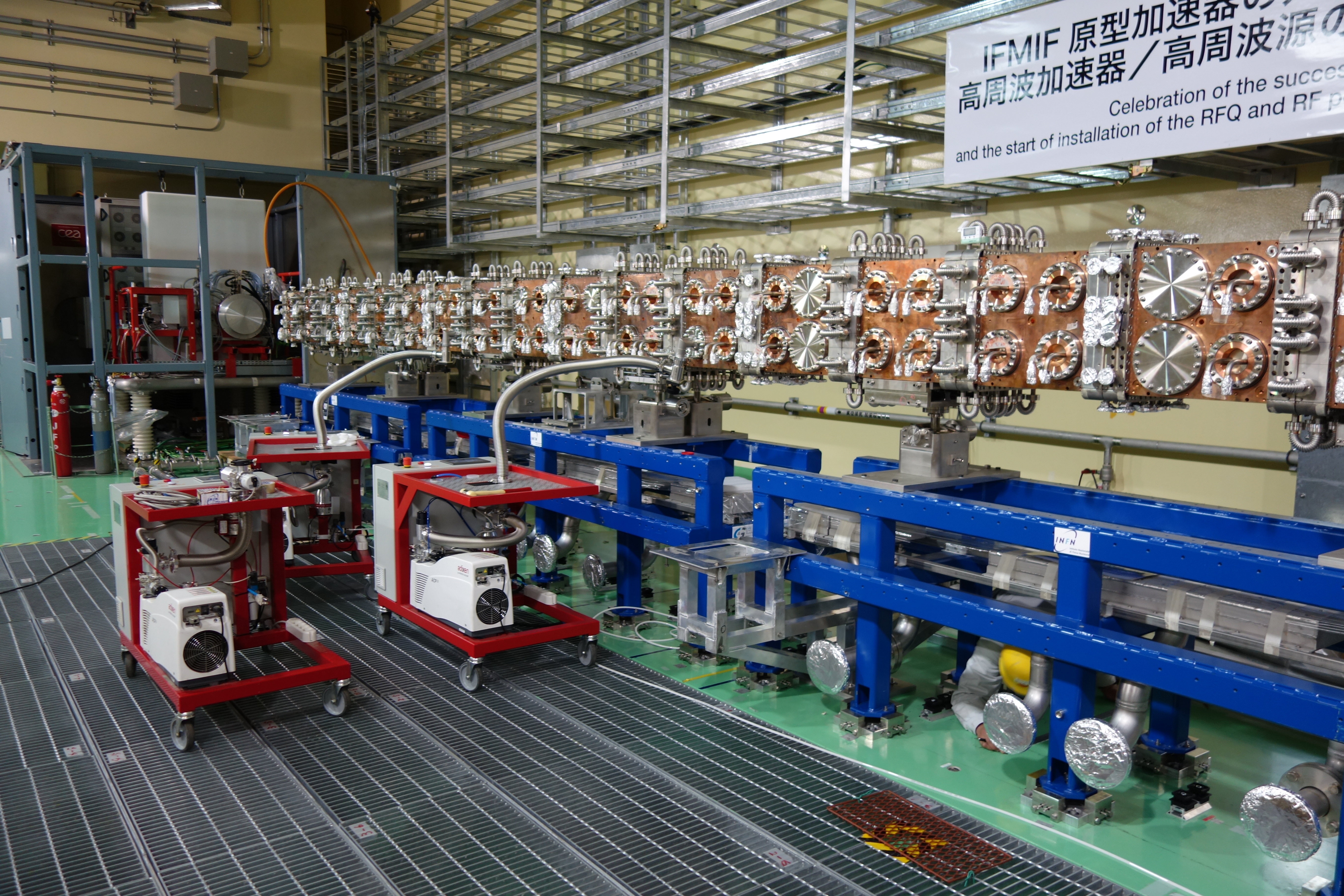

The meeting was successful in spite the overlapping of Broader Approach Steering Committee half-yearly meeting (BASC) and LIPAc ceremony. The main actors who have done all the technical work could also attend LIPAc ceremony and finally to the pleasant banquet that took place in the Kizan restaurant in Misawa, together with all ceremony participants for the celebration of success of the Injector commissioning and the start of installation of the RFQ and RF power generation for the LIPAc.

See you at the next LTM10 at the end of November 2016, again in Rokkasho (Japan)

7th LIPAc Technical Meeting

The 7th LIPAc Technical Meeting (LTM07) was held at Rokkasho, BA site Fusion Research Center (Japan) from 15th to 17th June 2015, and on the following two days Satellite meetings with more detailed technical discussions were held.

More than 40 experts from CEA (Saclay, France), INFN (Legnaro, Italy), JAEA (Rokkasho, Japan), CIEMAT (Madrid, Spain), F4E (Garching, Germany)and the IFMIF/EVEDA Project Team attended the meeting with additional European experts contributing remotely by videoconference.

The technical information that was presented at the meeting highlighted the significant progress achieved for the various components since the last LTM06 in November 2014.

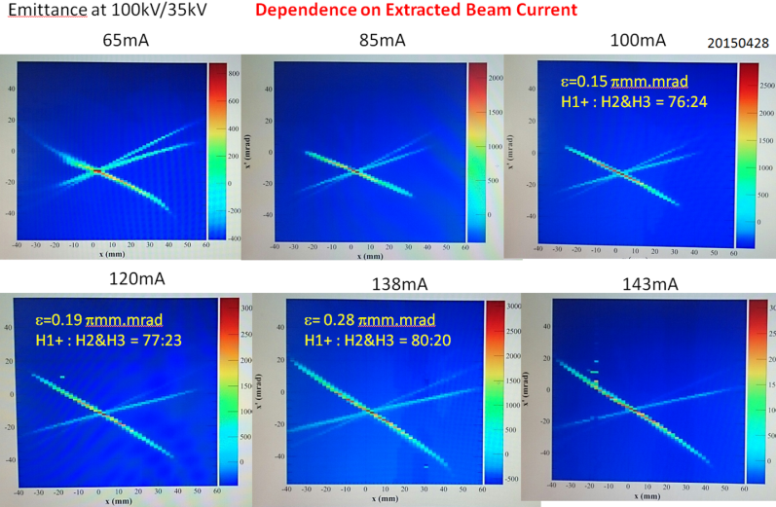

A particular highlight was the positive results that are presently obtained from the Injector commissioning as shown by the operation leader, Yoshikazu Okumura.

The main outcomes presented during this meeting are listed below:

Injector

The Injector commissioning resumed on April 22nd with the objective to complete the phase A1.2 (H+ beam, energy 50keV,variation d.c.,UIE,Itot) including the characterization and optimization of the proton beam. Performances of 100kV/155mA @ 20% duty cycle were reached during this campaign, allowing optimization of the beam emittance. Continuous wave (CW) operation was also tested successfully at 120 mA/100 kVeV, with 650 W RF power and SCCM gas flow rate.

The next important step is expected in July with the proposed start of deuterium operation (phase A1.3) after the Facility inspection by Radiation Authority.

RF power systems

Installation of transformers and the HV breakers on the electrical platform has started with JAEA contractor NKK. The contract for the remaining cable trays will be launched soon.

The delivery of the HVPS and RF power system for the RFQ is expected by the end of July 2015 at Rokkasho and its installation will take place upon its arrival.

- The RFQ super modules are nearing completion at INFN Legnaro (Italy) and will be shipped in December 2015 after the final acceptance test at Legnaro in November 2015. Cooling skid, piping and accessories will be shipped by the end of September 2015. The remaining components will be shipped to Rokkasho by February 2016.

- MEBT: much work has been completed in the last months to finish the manufacturing and the tests of the main components and auxiliaries. CIEMAT continue to push to have the beamline integrated for test by the end of this summer, with the aim to have the MEBT delivered to Rokkasho at the beginning of 2016.

- The LPBD detailed design is on going, was showed in the presentation its readiness for construction. Details for its cooling system were also discussed during the LTM.

- The SRF Linac design is completed and manufacturing contracts for the critical components have been placed. The licensing activities are on-going.

- The D-Plate is almost completed and will be ready for shipment by November 2014. Some activities of alignment of the components need to be confirmed by ensuring the reproducibility of the ideal accuracy expected.

- The HEBT and Beam Dump main components designs partially completed as already discussed in the previous LTM06 held last November 2015. Technical specifications are nearing completion and several manufacturing contracts have been launched

- Writing of the beam dump cooling system specification will start soon

- PPS-MPS,are now operational for injector commissioning. However, some modifications will be necessary for the next phase, especially with respect to the integration into the CCS, which is considered as an important milestone;

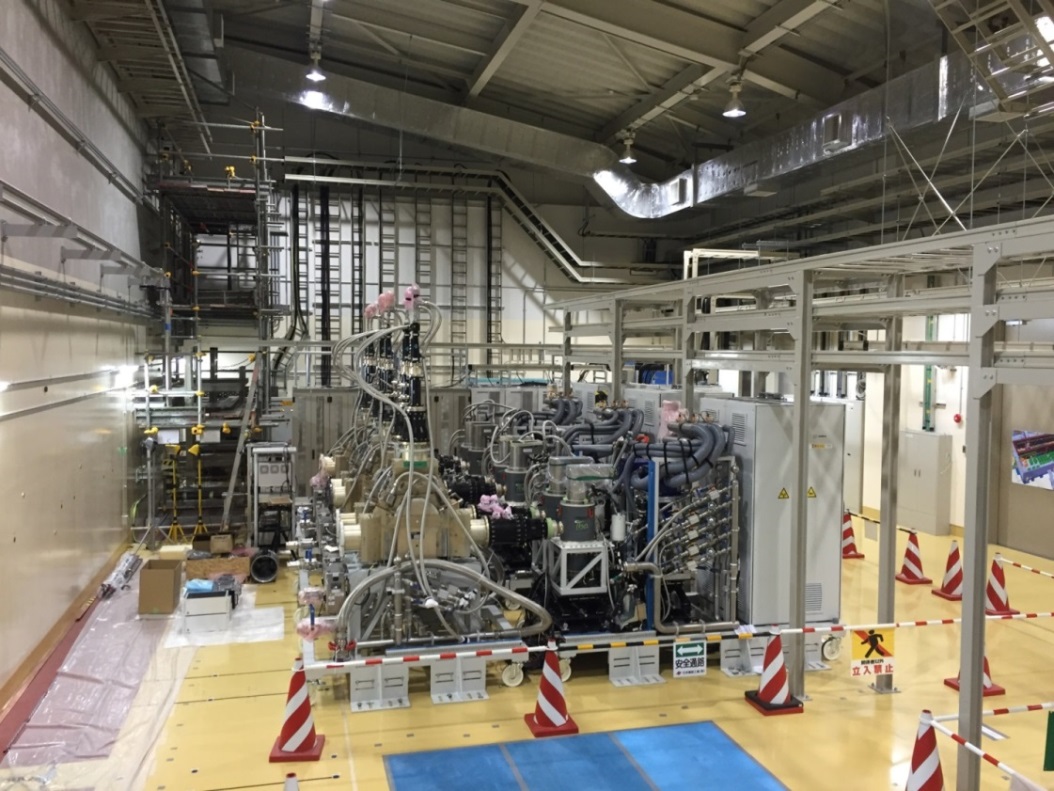

A site visit of the Accelerator Prototype Building was held, giving all attendees the opportunity to visit the vault and the RF area.

A pleasant event on the second day of the meetings was organized in a typical Japanese Restaurant in Rokkasho called “Darumaya”.

See you next LTM08 in Garching!

LTM08 will be held on Tuesday 24th, Wednesday 25th and Thursday 26th of November 2015.

Visit of prof. G. Rostagni and Dr. R. Piovan in Rokkasho (Japan)

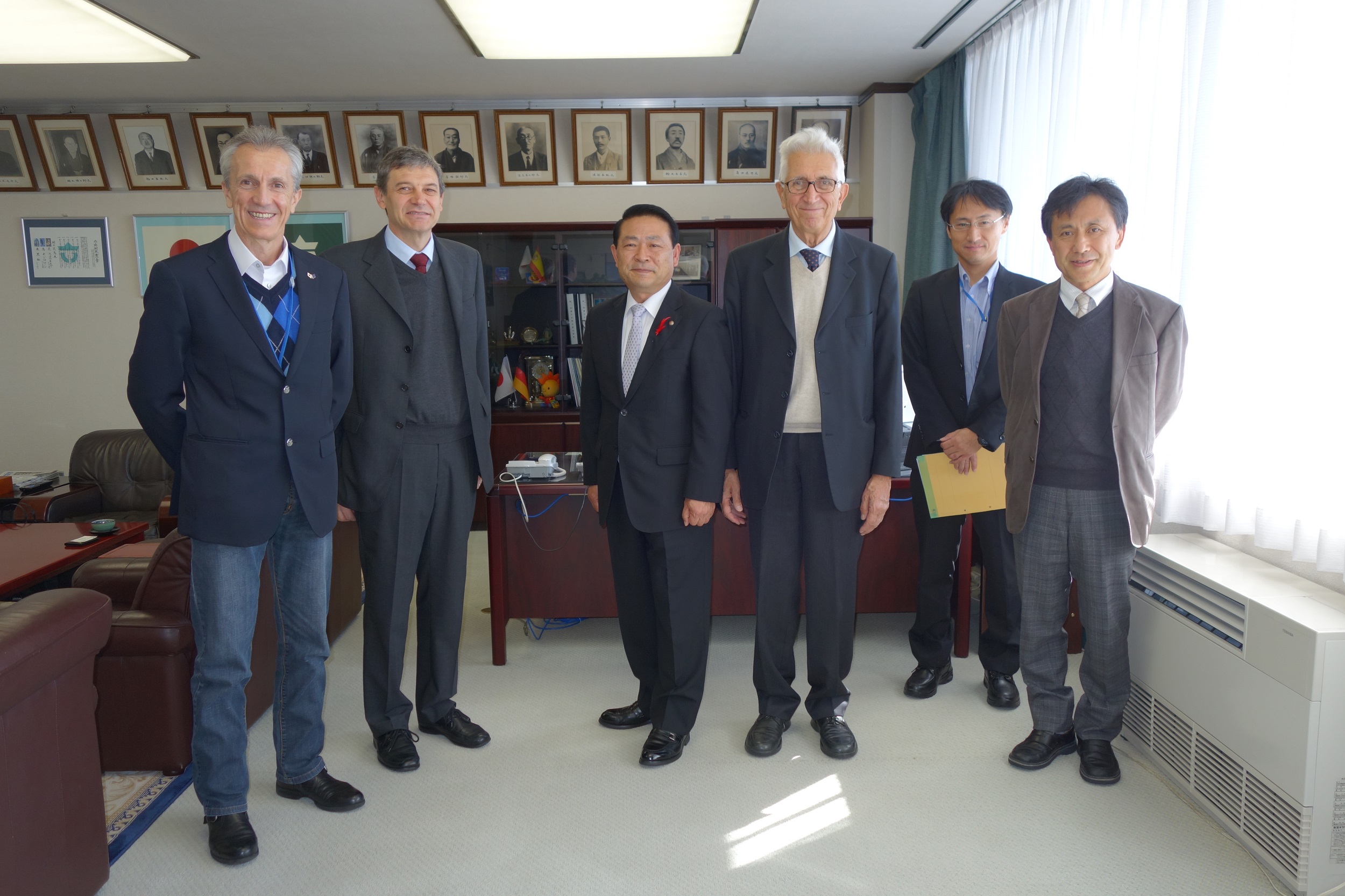

Prof. G.Rostagni, former RFX president and historical member of BA SC (Broader Approach Steering Committee) and Dr. G. Piovan, RFX director, visited Rokkasho on 23rd October 2015. Prof. G. Rostagni is our most senior supporter, following various attempts to visit Rokkasho, it has been possible his visit after almost 7 years from the last time at Rokkasho

The agenda of the meeting was eventful, started with the greeting visit to the deputy mayor of Rokkasho Susumu Hashimoto-san accompanied by G. Pruneri, K. Sakamoto and K.Hirata respectively; Section leader ILIC Unit, deputy IFMIF/EVEDA Project Manager and JAEA site Public Affair Manager.

To follow, chronologically, were visited: Japan Nuclear Fuel Limited Facility (JNFL), Wind Power Generation System and Solar Power Generation System, all facilities are located within Rokkasho area. Lunch took place at Rokka Pokka, the famous SPA in Rokkasho.

In the afternoon were made some presentations by K. Tobita (IFERC Director) on IFERC status and future plan, G. Pruneri and K. Okiai, respectively on IFMIF/EVEDA status and the introduction of activities foreseen by JAEA, for a post BA project (A-FNS)

Afterwards took place a visit to the LINAc Accelerator, Computer Center and Demo R&D Center, with a comprehensive detailed explanation of the facilities, respectively given by K. Sakamoto-G.Pruneri, Y. Ishii-K.Tobita and H. Tanigawa – S. Nakamichi

Finally the visit ended at Misawa, to the Takara-sushi restaurant for a dinner, with a very delicious food and with a pleasant attendance of BA activities’ management: S. Ohira, K. Sakamoto, K.Tobita, K. Okumura, K. Ochiai, G. Pruneri and F. Scantamburlo.

BA SC #16 has taken place in Naka on 21 April

Press Release

16th meeting of the Broader Approach Steering Committee

Naka (Japan), 21 April 2015

The Broader Approach Agreement between the EU and Japan supports the ITER project and the realization of fusion as a clean and sustainable source of energy for peaceful purposes.

The Broader Approach Agreement encompasses three research projects:

- “IFMIF/EVEDA”, to prepare for the construction of a materials test facility for future fusion reactors;

- The International Fusion Energy Research Centre (IFERC);

- The Satellite Tokamak Programme JT-60SA, a major upgrade of the tokamak JT-60

The working site for IFMIF/EVEDA and IFERC is Rokkasho (Japan), the site of the Satellite Tokamak Programme is Naka (Japan).

The Broader Approach is now in its eighth year and has become a model for effective international scientific collaboration, strengthening cooperation between the EU and Japan in delivering fusion as an energy source for the future.

Today (21 April 2015) representatives of the EU and Japan met at Naka Fusion Institute (Naka, Japan) for the 16th meeting of the Broader Approach Steering Committee and approved the 2014 Annual Reports and updates of the Project Plans for the three projects.

The initial beam test of the injector of the Linear IFMIF Prototype Accelerator in Rokkasho began producing scientific results in November 2014. The EVEDA Lithium Test Loop in Oarai has successfully demonstrated stable lithium flow for IFMIF operating conditions and has now completed its mission. The Test Facility Validation activities have been successfully accomplished.

The Helios supercomputing system (Roku-chan) has been in routine use since 2012 by researchers from the EU and JA resulting in many high-quality scientific papers. The Intermediate Report on DEMO Design has been complied focusing on a technical perspective of DEMO on the basis of evaluation and assessment of critical design issues. The DEMO R&D project has studied the compatibility of SiC and SiCf/SiC composites with liquid Pb-Li alloy. The results have been added to the database for the study of the liquid blanket.

Satellite Tokamak Programme (JT60-SA)

The main components manufactured in Europe – the Quench Protection Circuit, the High Temperature Superconducting Current Leads and the Cryoplant for the superconducting magnet, have now been delivered and are being installed. Nine of the ten Vacuum Vessel sections are already sitting on the base and the welding of the sections is progressing well.

These remarkable achievements were celebrated by a ceremony on 20th April attended by dignitaries from Japan and the EU which included representatives of the European Commission, France, Germany, Italy and Spain.

The Steering Committee expressed appreciation for the great efforts of the Aomori Prefecture and Rokkasho Village in producing high quality living and educational support for the EU researchers and their families in Rokkasho.

The 17th Broader Approach Steering Committee meeting will be held in Italy on 11 December 2015.

8th LIPAc Technical Meeting

The 8th LIPAc Technical Meeting (LTM08) was held at the Garching antenna of Fusion for Energy (F4E) from 24th to 26th November 2015. More than 30 experts from different involved institutes, including CEA (Saclay, France), INFN (Legnaro, Italy), JAEA (Rokkasho, Japan), CIEMAT (Madrid, Spain), F4E (Garching, Germany) and the IFMIF/EVEDA Project Team; attended the meeting. In addition, Japanese experts from KEK and J-PARC were invited to attend on behalf of JAEA.

The first day was devoted to satellite meetings where the cryomodule assembly and licensing; and the control system were discussed in detail.

Detailed technical information was presented highlighting the significant progress that has been made for the manufacture and installation of various components since the previous LTM07 (held in Rokkasho on 15-17 June). The progress on Injector commissioning, as shown by the Deputy Director of the Department of Fusion Reactor Materials research at the JAEA Rokkasho Fusion Institute, Keishi Sakamoto, on behalf of Yoshikazu Okumura, the Head of the ILIC unit; was warmly appreciated.

Key activities which were completed on site during 2015 include:

- 29 June : Establishing the radiation controlled area

- 7 July : 1st D+ beam

- 15 July : Facility inspection

- 1 Sep : 1st arrival of the RF module to Rokkasho

- 9 Sep : Start phase A-2

- 22 Oct : Injector LCS upgrade

- 9-13 Nov : Injector resistor repair

The main outcomes presented during the meeting are listed below:

- Injector

Injector commissioning resumed on 22nd April, and the first deuterium beam was produced two months later on 22nd July 2015 after receiving the authorization from the Regulatory Authority on 15th July. With the change of the plasma electrode aperture diameter from 10 mm to 12 mm, a 100keV/145mA/9.5% Deuteron beam was produced. The upgrade and integration of the Local Control System into Central Control System was completed on 23rd October.

- RF power systems

Installation of seven HVPS’s and two RF modules for the RFQ, transformers and the HV breakers on the electrical platform was nearly completed. While the activity continues, there has also been much progress in the installation of cable trays inside the RF area.

- RFQ

The RFQ will be shipped from Legnaro (Italy) to Japan by air freight by the end of January 2016, while the associated cooling skid, piping and accessories will be shipped during December 2015. All remaining components will be shipped to Rokkasho by the end of April 2016.

On behalf of JAEA, Feedback was provided by Morishita-san explaining his experience of RFQ construction, installation and commissioning at J-PARC in Japan.

- MEBT

With the exception of the second buncher, for which the tests are ongoing, all MEBT subcomponents have passed their acceptance tests. The assembly of the subcomponents is approaching completion, and it is expected that the complete MEBT will be sent to Rokkasho by the end of January 2016.

- LPBD

Manufacture of The LPBD is underway, and will be completed in early 2016.

- SRF Linac

Manufacturing contracts for all critical components have been placed, and the tender process for a number of non-critical-path items has started. Licensing activities for the complete cryomodule continue, and informal approval for the cavity design has been given by KHK. Formal approval is expected soon.

Sakai-san (KEK) presented KEK’s experience of installation and commissioning of the cERL SRF LINAc. While the cERL LINAc is fundamentally different to IFMIF / EVEDA’s, the presentation provided useful insight which will be considered as the detailed cryomodule assembly procedure is developed.

- D-Plate

Assembly of the D-plate is nearing completion, and the fully integrated and aligned assembly will be ready for shipment at the end of January 2016.

- HEBT/Beam Dump

The water cooling skid was recently tested and is now ready for shipment. Preparation of the shipping contract is underway, and the skid will be shipped by the end of December 2015. The main components of the Beam Dump conceptually designed and the detailed design is progressing. Technical specifications for a number of HEBT components are nearing completion and several manufacturing contracts have been launched, particularly electro deposition for the inner cone which started in November 2015

- PPS-MPS

The Personnel Protection System has been modified to comply with regulatory requirements. The Machine Protection System has been enhanced to comply with the evolving operational requirements for injector commissioning. The Injector LCS has been fully integrated into the CCS.

A pleasant event on the second evening of the meetings was held at restaurant “Maisberger hotel” at Neufahrn

See you at the next LTM09 in Rokkasho (Japan)!