The last IFMIF/EVEDA Project Committee recommended to resume LIPAc beam operations in a timely manner. For what concern the RFQ couplers, this recommendation resulted in the re-use of viton Oring solution for ceramic window sealing with improved cooling capacity while the ceramic-metal brazed couplers would be conditioned as much as possible in parallel.

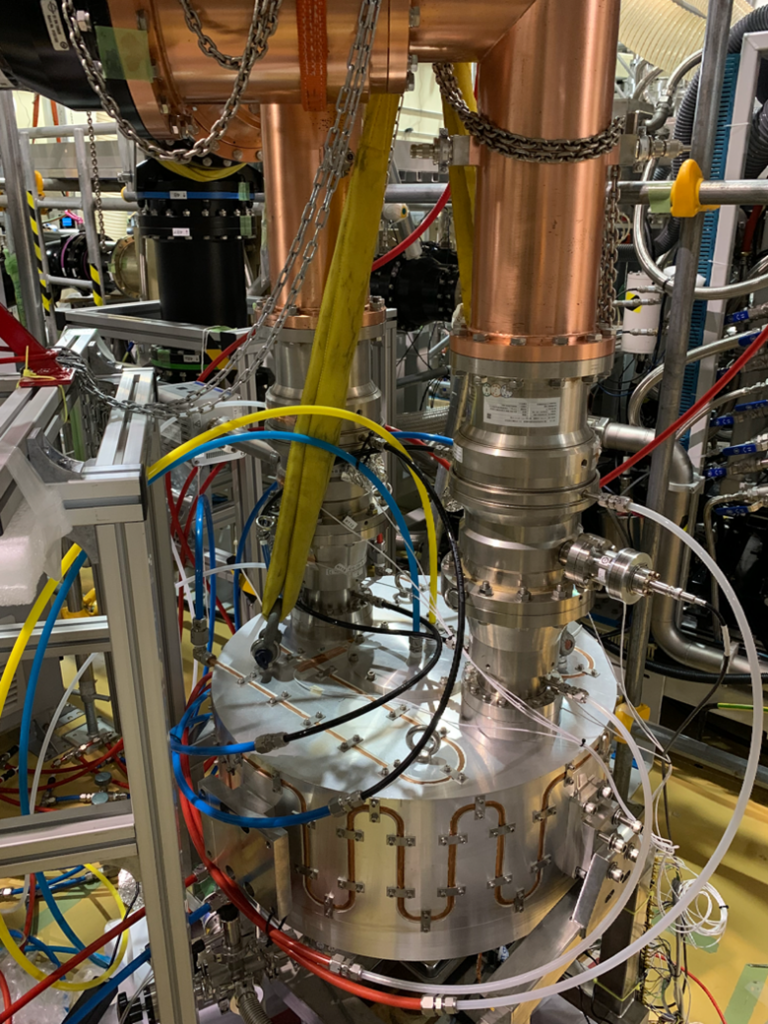

Indeed, the design of the RFQ Oring coupler has been updated to improve its cooling capability. On vacuum side, an upgraded anchor is meant to ease the heat extraction from the internal conductor and the RF windows ceramic. A prototype was built and tested in Rokkasho, confirming its assembly procedure and vacuum tightness. On atmospheric side, flanges of the RF windows were machined to allow compressed air-cooling injection and extraction by 6 holes. The series of upgraded anchors and air flanges were delivered in Rokkasho beginning of February. The re-installation of the Oring couplers with upgraded elements on the RFQ is starting this week.

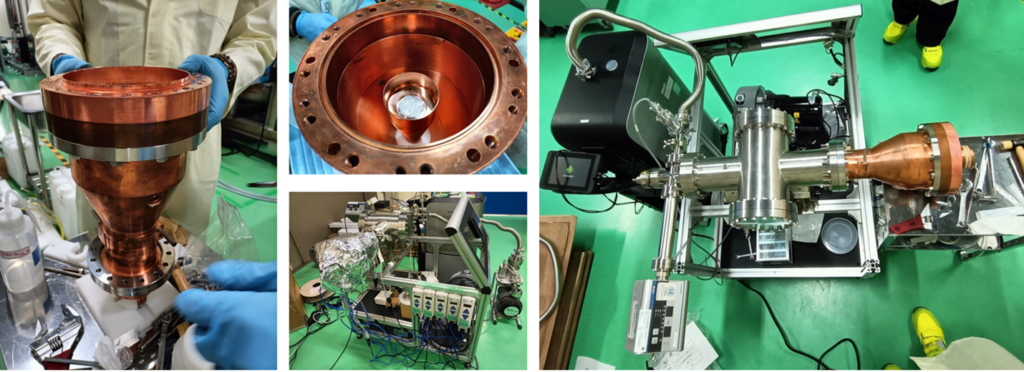

Meanwhile, an important effort was dedicated to the setup of the High-Power Test Bench (HPTB) in the RF area with the objective to condition the RFQ brazed couplers. The LIPAc building was not designed to host this kind of HPTB and the RF area was already occupied by many equipment. Resources from the different groups of the LIPAc Unit were involved to find solutions for the HPTB, finding adequate position, re-using existing components and adapting the RF system and control system to operate the HPTB in standalone. Careful conditioning of the first pair of brazed couplers started in Dcember 2022 and reached 96% Duty Cycle (DC) last week. The objective is to reach 100% DC in order to validate the design of this brazed couplers. The 3 other pairs will need to be conditioned as well to validate their manufacturing, presumably on a different test bench as the HPTB will be shortly dismounted.

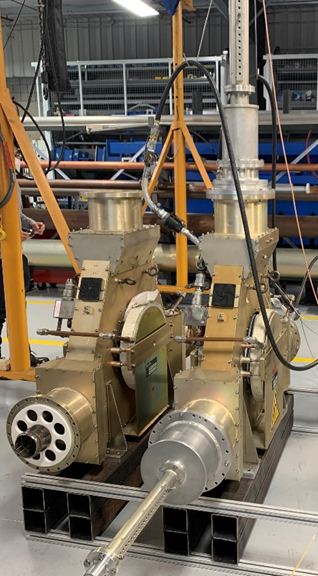

The circulator 1B was checked and repaired at the premises of the manufacturer (Ferrite Company owned by MEGA) in Gorham, near Portland, ME-USA. The Factory Acceptance Tests (FAT) were organized last week with the attendance of 3 LIPAc Unit experts. For the FAT, the circulators 1A and its twin unit 1B were mounted together in the same configuration as for LIPAc (see picture below). Electrical performance tests and water tightness tests were passed successfully. After reaching thermal stability, RF parameters were measured on circulator 1B to check the success of the repair. The measurements were repeated after removing circulator 1A, resulting in a strong mismatch that can be corrected applying adequate current to the coil. This series of measurements will be useful to setup the spare circulator which aims to have an interchangeable position between side A and B. Both circulators will be packed for shipment to be back in Rokkasho by end of March.