The primary objective of the IFMIF Engineering Design Activities, as a sub-project of the IFMIF/EVEDA Project, is to produce a complete and fully integrated engineering design of the IFMIF plant by incorporating the technical feedback from the accompanying validation activities of key technological elements.

The engineering design of the IFMIF plant is intimately linked with the validation activities, and was conducted during the first phase of the IFMIF/EVEDA project. The IFMIF Intermediate Engineering Design Report was established in June 2013 and adopted by the stakeholders in December 2013. The IFMIF Intermediate Engineering Design defines the major systems in outline.

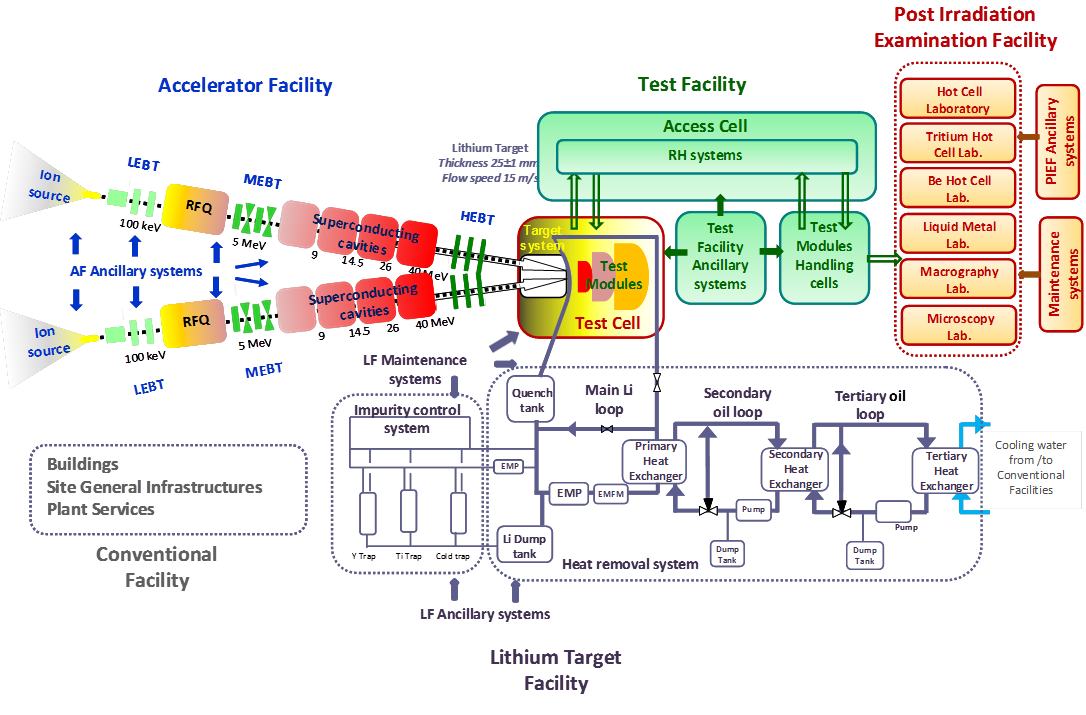

Accelerator Facility: The two accelerator CW deuteron beams of 5 MW each impinge in an overlapping manner at an angle of ±9° with a footprint of 200 mm x 50 mm and a steady time profile on the liquid Li jet, with the Bragg’s peak absorption region at about 20 mm depth.

The Target Facility, which holds the inventory of about 10 m3 of Li, forms and conditions the beam target. The Li screen fulfils two main functions: 1) to react with the deuterons to generate a stable neutron flux in the forward direction and 2) to dissipate the beam power in a continuous manner. The flowing Li (15 m/s; 250 °C) is shaped and accelerated in the proximity of the beam interaction region by a two-stage reducer nozzle forming a concave jet of 25 mm thickness with a minimum radius of curvature of 250 mm in the beam footprint area. The resulting centrifugal pressure raises the boiling point of the flowing Li and thus ensures a stable liquid phase. The beam power absorbed by the Li is evacuated by the heat removal system and the lithium is cooled to 250 °C by a serial of heat exchangers. The control of impurities, essential for the quality of the liquid screen, will be done through a tailored design of cold and hot trap systems, and purities of Li during operation better than 99.9% are expected. On-line monitoring of impurities will detect impurity levels over 50 ppm. Based on numerical analyses carried out in the last three decades, the beam-target interaction is not expected to have a critical impact on jet stability.

The Test Facility will provide high, medium and low flux regions ranging from ›20 dpa/full power year (fpy) to ‹1 dpa /fpy with increasingly available irradiation volumes of 0.5 l, 6 l and 8 l that will house different metallic and non-metallic materials potentially subjected to the different irradiation levels in a power plant. More specifically, in the high flux region, fluences of 50 dpa in ‹3.5 years in a region of 0.5 l, together with power plant relevant fluences of ›120 dpa in ‹5 years in a region of 0.2 l, are planned. The high flux region will accommodate about 1000 small specimens assembled in 12 individual capsules independently temperature controlled that will allow not only mechanical characterization of the candidate structural materials tested, but also an understanding of the influence in their degradation with material temperature during irradiation.

The Post-Irradiation Examination Facility, an essential part of IFMIF, is hosted in a wing of the main building in order to minimize the handling operations of irradiated specimens.It will not only allow testing irradiated specimens out of the different testing modules, but also characterizing metallographically the specimens after destructive testing.

The IIEDR is composed of 5 major sections: 1) an “Executive Summary”; 2) the ‘‘IFMIF Plant Design Description’’ (PDD), that also includes the Executive Summary, summarizes the content of the full IIEDR that is formed by above 100 technical reports; 3) a (confidential) cost and schedule report, based on the experience gained with the construction of prototypes during the EVA phase and the help of Japanese and European prominent engineering companies; 4) Annexes to the PDD; and 5) 34 Detailed Design Description documents of all the sub-systems supporting the PDD. The second item (IFMIF PDD) is also available as a printed report.

The ‘‘IFMIF Intermediate Engineering Design Report’’ (IIEDR) was released in December 2013 following the recommendations of a Quality Review Panel raised by the Steering Committee of the BA. All documents of the EDA phase have been archived and are accessible through IFMIF’s internal electronic database. Last but not least, a Risk Register document assessing the project risks have been carefully developed.