In the first months of 2022 the operations on-site are focused on the CW conditioning campaigns for the injector and the RFQ.

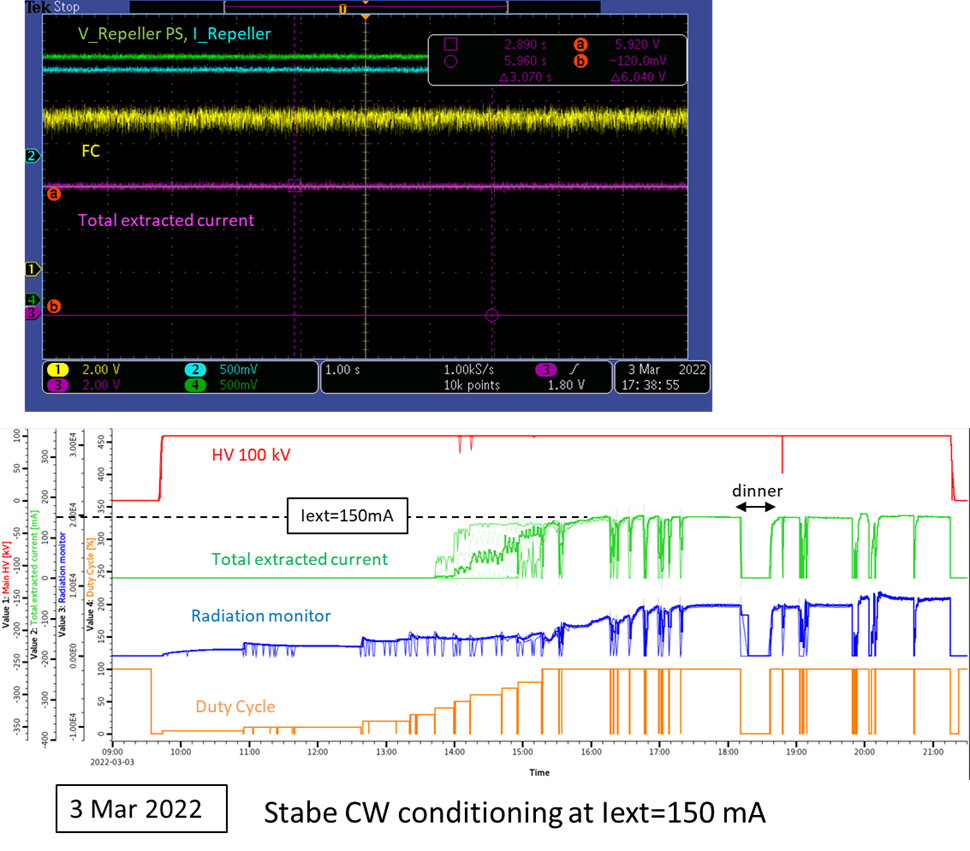

The injector conditioning campaign makes steady and quick progresses: the commissioning with 11mm plasma electrode reached 155mA of total extracted beam current in CW already several times. Fine tuning of several parameters is on-going to improve the stability of the beam (decrease the sparks, current fluctuations, improve emittance etc.) and determine a stable working point for long term CW operation.

The RF-RFQ conditioning suffered a stop in February because of a serious damage at the circulator of the RF-RFQ chain#1b. After abnormal operations and high number of arcs during conditioning in the chain#1b, the circulator was opened and the connection point between the inner plate of the circulator and the matching section of coax line was found to be broken. The EU and QST teams on-site have reacted calmly and with great spirit of collaboration and proceeded to: analyse the accident, determine the possible causes, inspect carefully all other circulators connections and define an action plan with associated risk analyses. The supplier of the circulator was contacted and we are in the process to order spare parts to repair the circulator on-site. In parallel the procurements of spares circulators will be launched. A study has been performed and associated documents and procedures have been approved to resume conditioning of the RFQ by using 7 RF-RFQ chains (out of the 8 available, i.e. with chain#1b being off). In these days a dummy load has been installed on the coaxial line of chain#1b to manage the reflected power during RF injection and RF-RFQ conditioning has just resumed.

It is difficult to have a clear idea about the impact on the schedule: the repair of the circulator on-site is planned in April and assuming that RF-RFQ conditioning will be resumed with 8 chains, we might reach CW operation by beginning of June. This will leave a couple of months for beam operation before the yearly summer maintenance break.

We had also several remote sessions with CIEMAT support to solve punctual issues (like a problem on a limit switch of a motor driven drain valve for the Beam Dump cartridge in the vault, to install the SW for a newly installed radiation resistant RGA in the HEBT) and to keep progressing in the finalization of the vacuum machine state for the HEBT.

The Diagnostic team has been working to recover full operability of the Beam Position Monitors and is currently also checking the SEM grids. The Fluorescence Profile Monitor installed in the HEBT have been moved out of the vault for a necessary recalibration that is ongoing.

We had support of a subcontractor on-site to finalize the maintenance of cooling skid (with replacement of mechanical seals in several pumps) and some re-installation work of N2 gas system in the deaerator loop of the Beam Dump skid.

Disclaimer: the information reported is not meant to be technically complete and doesn’t cover all the activities currently carried out on LIPAc.